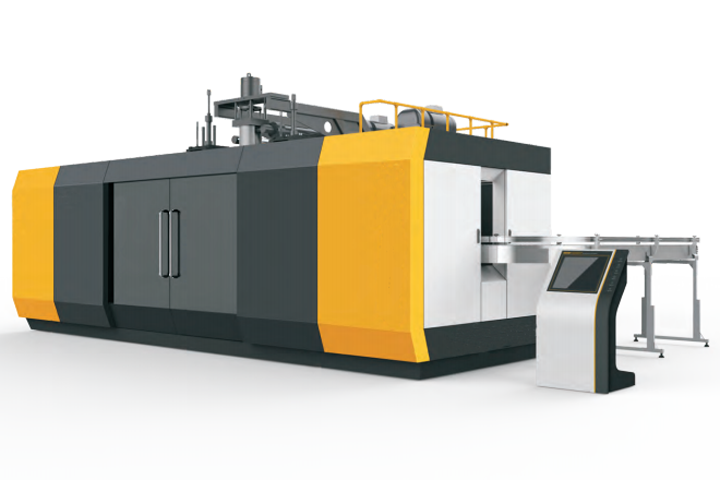

High Speed Fully Electric Blow Bottle Machine | ZQ-G15L-2

High Speed Fully Electric Blow Bottle Machine

1 .The machine use continuous rotation system with multiple safety protection devices to ensure the high speed preform feeding.

2 .The preform feeding without turning device,simple structure,convenient maintance, reduce cost of spare part change.

3 .The heating pitch between the preforms is small,effectively using the heating space of the lamp tube,and improving the heating efficiency enery saving by variable pitch structure.

4 .The water runs directly through the heating channel with air cooling system to protect preform neck from deformation.

5 .Optimize oven air draft and preform surface cooling.Reversible heating box make it more easy to change lamp.

6 .Mould closing adopts CAM linkage,no chain plate pin shaft small size, long service life.

7 .The stepping servo motor ensure high-speed operation and accurate positioning.

8.Servo moto is used to drive the stretching and blowing station,equipped with high speed precision blowing valve set to achieve high production requirements.

9.Stainless steel pipe make the air blowing more clean without pollution.

10 .High pressure recycle system reduce power consumption.

11 .Multiple direction positioned for the autoloader make it more flexibly for installation.

12 .The machine is desighed to be compact in size.effectively reducing floor space.

Main Machine Infromation.

1 .The machine use continuous rotation system with multiple safety protection devices to ensure the high speed preform feeding.

2 .The preform feeding without turning device,simple structure,convenient maintance, reduce cost of spare part change.

3 .The heating pitch between the preforms is small,effectively using the heating space of the lamp tube,and improving the heating efficiency enery saving by variable pitch structure.

4 .The water runs directly through the heating channel with air cooling system to protect preform neck from deformation.

5 .Optimize oven air draft and preform surface cooling.Reversible heating box make it more easy to change lamp.

6 .Mould closing adopts CAM linkage,no chain plate pin shaft small size, long service life.

7 .The stepping servo motor ensure high-speed operation and accurate positioning.

8.Servo moto is used to drive the stretching and blowing station,equipped with high speed precision blowing valve set to achieve high production requirements.

9.Stainless steel pipe make the air blowing more clean without pollution.

10 .High pressure recycle system reduce power consumption.

11 .Multiple direction positioned for the autoloader make it more flexibly for installation.

12 .The machine is desighed to be compact in size.effectively reducing floor space.

Main Machine Infromation.

| 项目 ITEMS | UNIT | ZQ-G600-8 | ZQ-G600-10 | ZQ-G5L-3 | ZQ-G5L-4 | ZQ-G15L-2 | |

| 瓶型规格 CONTAINER | Number of Cavities | PC | 8 | 10 | 3 | 4 | 2 |

| Max.Bottle Capactity | L | 0.6 | 0.6 | 5 | 5 | 15 | |

| Max.Neck Diameter | mm | 30 | 30 | 50 | 50 | 60 | |

| Max.Bottle Diameter | mm | 70 | 70 | 180 | 180 | 250 | |

| Max.Bottle Height | mm | 300 | 300 | 350 | 350 | 500 | |

| Theoretical Output | B.P.H | 16000-18000 | 20000-22000 | 3000-3500 | 4000-4500 | 2300-2600 | |

| 成型组规格 MOLDING | Spindle Chain Pitch | mm | 38 | 38 | 60 | 60 | 76 |

| Bottle Cavity Pitch | mm | 80 | 80 | 200 | 200 | 280 | |

| 电力规格 ELECTRICAL POWER | Max.heating Power | KW | 60 | 60 | 80 | 80 | 120 |

| Servo Motor Power | KW | 17.5 | 22 | 14.5 | 19.5 | 19 | |

| Other Motor Power | KW | 5 | 5 | 5 | 5 | 5 | |

| Total Power | KW | 83 | 87 | 100 | 105 | 144 | |

| Voltage/Frequency | V/HZ | 380±10% 50HZ/220V±10% 60HZ | |||||

| 空压规格 AIR SYSTEM | Operating Pressure | Bar | 7 | 7 | 7 | 7 | 7 |

| Low pressure Air Consumption | L/min | 1000 | 1000 | 1000 | 1000 | 1000 | |

| Blowing Pressure | Bar | 35 | 35 | 35 | 35 | 35 | |

| High Pressure Air Consumption | L/min* | 8000 | 9000 | 10000 | 14000 | 12000 | |

| 模具冷却水MOLD COOLING WATER | Operating Pressure | Bar | 3-5 | 3-5 | 3-5 | 3-5 | 3-5 |

| Temperature Range | ℃ | 10-12 | 10-12 | 10-12 | 10-12 | 10-12 | |

| Flow Rate | L/min | 50 | 50 | 50 | 50 | 50 | |

| Cooling Capacity | HP | 5 | 5 | 5 | 5 | 5 | |

| 加热器冷却水 HEATER COOLING WATER |

Operating Pressure | Bar | 3-5 | 3-5 | 3-5 | 3-5 | 3-5 |

| Temperature Range | ℃ | 10-15 | 10-15 | 15-20 | 15-20 | 15-20 | |

| Flow Rate | L/min | 50 | 50 | 50 | 50 | 50 | |

| Cooling Capacity | HP | 5 | 5 | 5 | 5 | 5 | |

| 机台规格MACHINE | Size(L*W*H) | M | 5.6*1.5*2.6 | 6.2*1.5*2.6 | 5.0*1.6*2.6 | 6*1.6*2.6 | 5.3*1.85*3.0 |

| Weight | KG | 6000 | 7000 | 6000 | 7000 | 7000 | |

| 备注REMARK | 1.*理论产量按容量500ml水瓶为例,最终产能依据瓶胚、瓶型及容量而定。 The theortical output is based on 500ml bottle shape,the final production capacity is based on the preform,bottle design and volume. | ||||||

| 2.*高压耗气量按容量500ml水瓶为例,最终根据瓶子容量和产能而定。The high pressure air consumption is based on the 500ml bottle,the final consumption will depend on the bottle volume and output. | |||||||