PET Preform Injection Molding Systems

PET Preform Injection Molding Systems

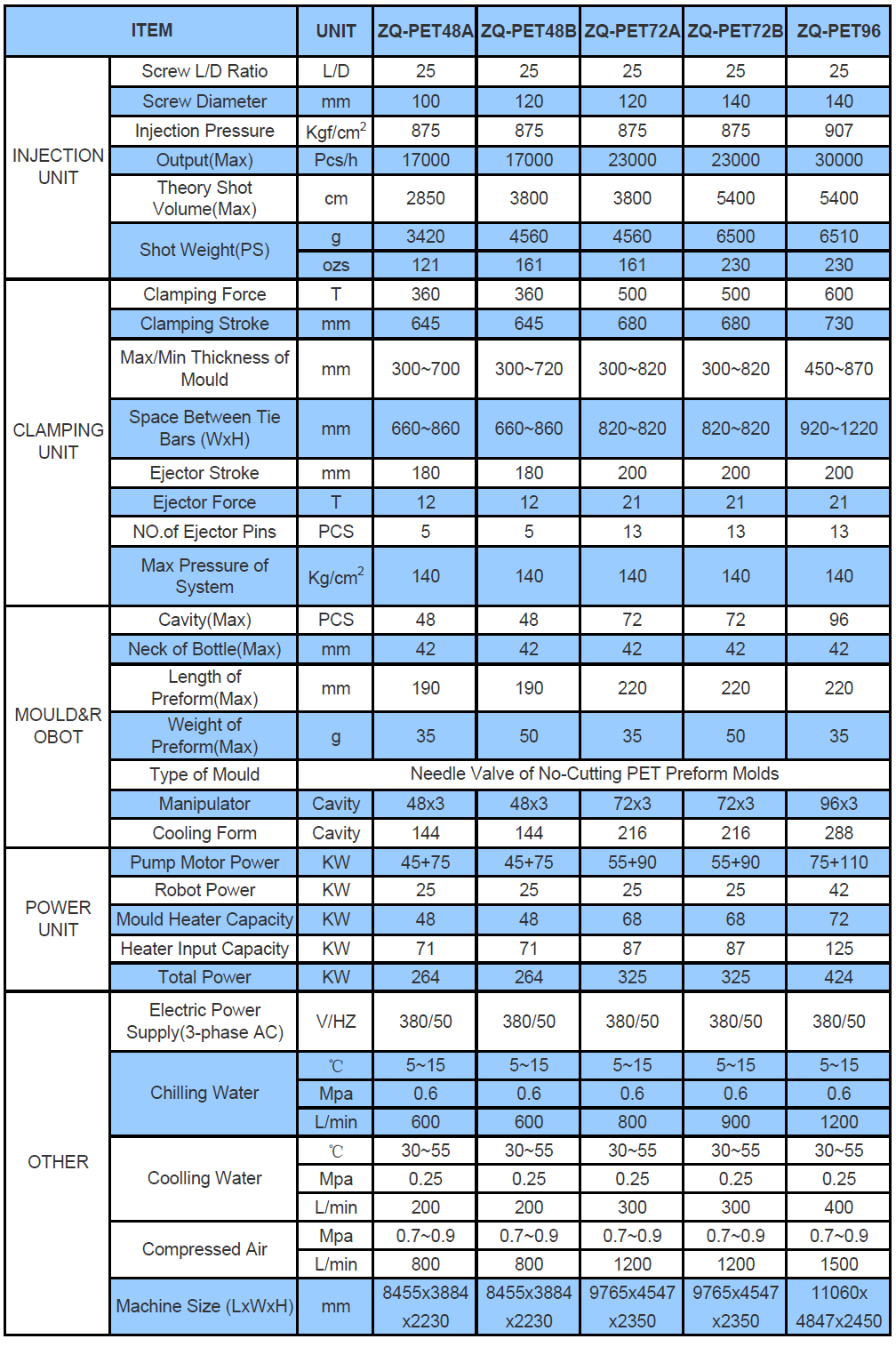

ZQ 32,48,72,96 cavities PET preform injection molding systems uses a new part cooling and handling system, which features:

1. Cooling on the inner surface of the preform without using compressed air, unlike most post-mold cooling systems which only cool the outer surface

2. Optimized cycle utilization — being mounted on the moving platen, the cooling system remains active for up to 85% of the overall cycle.

PET preform injection molding systems are available from 280 to 500 tonnes (2800 to 5000 kN) and up to 96 cavities.

PET injection systems offer:

1. Faster cycles

2. Reduced energy consumption

3. Smaller footprint

4. Improved repeatability

5. Rapid set-up

Machine Features:

1. Two state plasticizing enables plenty injection quantity;

2. Take out plate with three working position insures sufficient cooling time and shorter cycle time;

3. High quality parts and accessories from world famous brands enable higher speed and precision;

4. Special screw design increases torque while brings down shear force to avoid degradation;

5. Accumulator from world reputable manufacture increases performance while brings down power consumption;

Reflex Platens

Reflex platens distribute clamp force evenly across the platen face.

1. Allow for 10-30% lower clamp tonnage

2. Decrease mold wear

3. Improve part quality

Injection Units

ZQ systems offer both reciprocating screw (RS) and two-stage injection units. RS units offer the performance required for many PET applications while two-stage is appropriate for higher throughput applications.

Controls

ZQ-based controls manage all functions of our PET production systems, with optional packages to integrate auxiliaries and downstream part handling equipment. Advantages include:

1. Faster cycle times

2. Improved shot-to-shot repeatability

3. Remote connectivity through ServiceNetLink

4. Control of molding system and auxiliaries from a single interface

Linear Bearings

Linear bearings support the moving platen directly on the machine base. This design reduces mold wear by improving platen alignment and perpendicularity, and provides a grease free molding environment.

Note: The specifications are subject to change without notice for the further improvement. Custom production accepted. Any client idea tried.

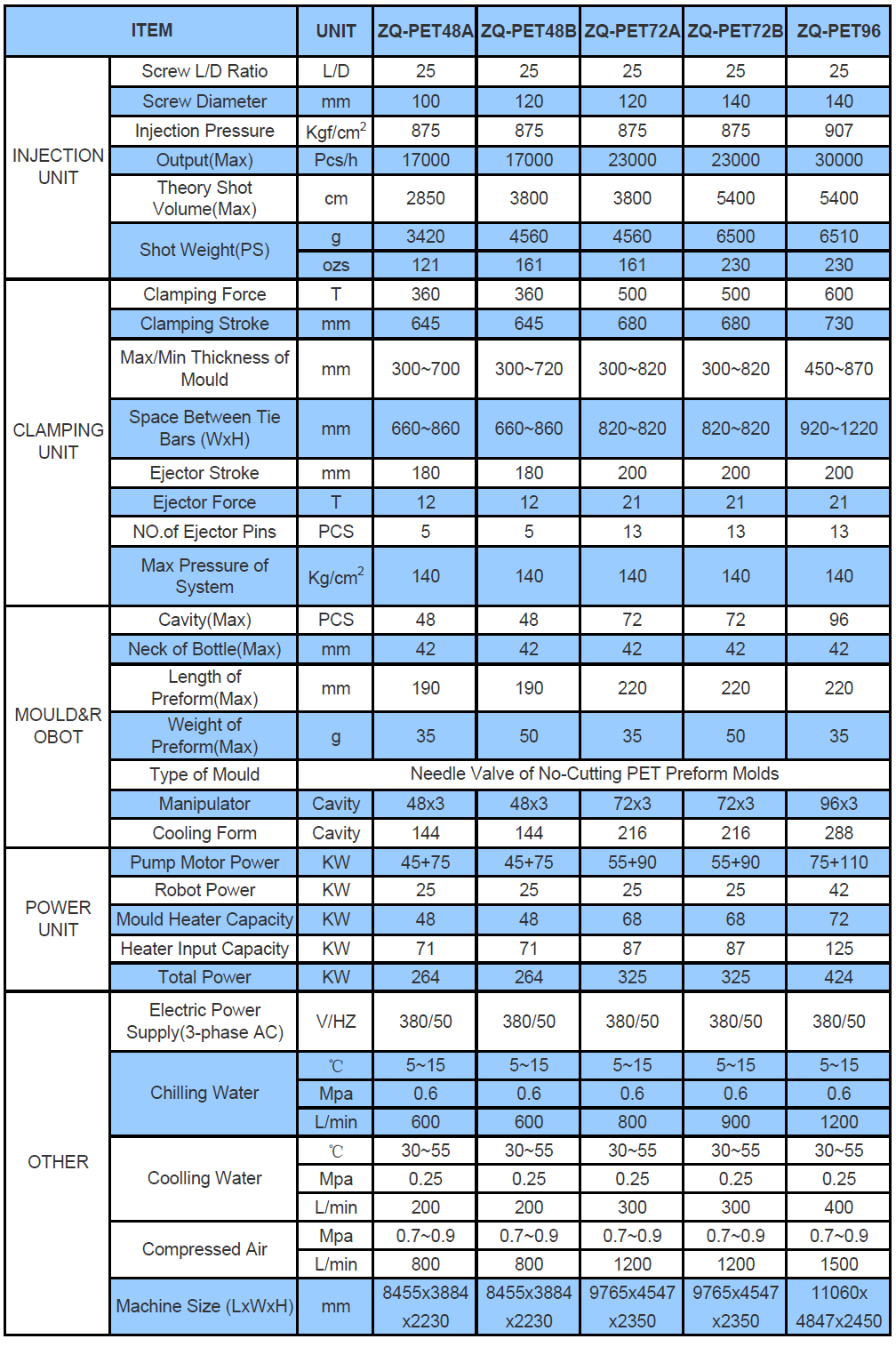

ZQ 32,48,72,96 cavities PET preform injection molding systems uses a new part cooling and handling system, which features:

1. Cooling on the inner surface of the preform without using compressed air, unlike most post-mold cooling systems which only cool the outer surface

2. Optimized cycle utilization — being mounted on the moving platen, the cooling system remains active for up to 85% of the overall cycle.

PET preform injection molding systems are available from 280 to 500 tonnes (2800 to 5000 kN) and up to 96 cavities.

PET injection systems offer:

1. Faster cycles

2. Reduced energy consumption

3. Smaller footprint

4. Improved repeatability

5. Rapid set-up

Machine Features:

1. Two state plasticizing enables plenty injection quantity;

2. Take out plate with three working position insures sufficient cooling time and shorter cycle time;

3. High quality parts and accessories from world famous brands enable higher speed and precision;

4. Special screw design increases torque while brings down shear force to avoid degradation;

5. Accumulator from world reputable manufacture increases performance while brings down power consumption;

Reflex Platens

Reflex platens distribute clamp force evenly across the platen face.

1. Allow for 10-30% lower clamp tonnage

2. Decrease mold wear

3. Improve part quality

Injection Units

ZQ systems offer both reciprocating screw (RS) and two-stage injection units. RS units offer the performance required for many PET applications while two-stage is appropriate for higher throughput applications.

Controls

ZQ-based controls manage all functions of our PET production systems, with optional packages to integrate auxiliaries and downstream part handling equipment. Advantages include:

1. Faster cycle times

2. Improved shot-to-shot repeatability

3. Remote connectivity through ServiceNetLink

4. Control of molding system and auxiliaries from a single interface

Linear Bearings

Linear bearings support the moving platen directly on the machine base. This design reduces mold wear by improving platen alignment and perpendicularity, and provides a grease free molding environment.

Note: The specifications are subject to change without notice for the further improvement. Custom production accepted. Any client idea tried.